Stripping (blasting/ water jetting) and painting mobile robots

Steel structures need regular stripping and painting in order to avoid corrosion. stripping is a difficult operation causing hardship for workers.

Any solution bringing automation improves working conditions.

In addition, we face more and more the following problematics on steel large parts:

– Accessibility : work at height on ship’s hull, confined space operations inside penstocks, work at height with difficult access outside penstocks.

– Containment : lead or asbestos presence in old coatings requires a full containment of the working area.

For all those reasons, ACRI INGENIERIE has developed various robotised stripping and painting solutions.

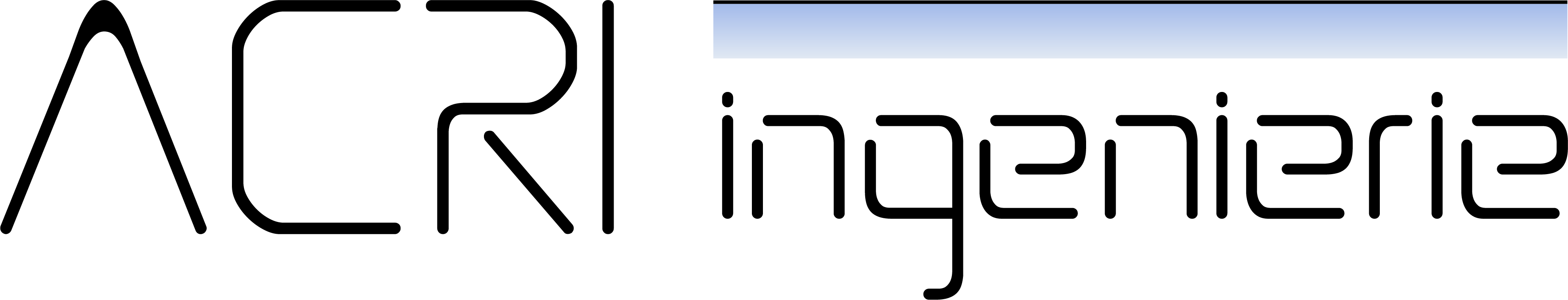

La Coche, project:

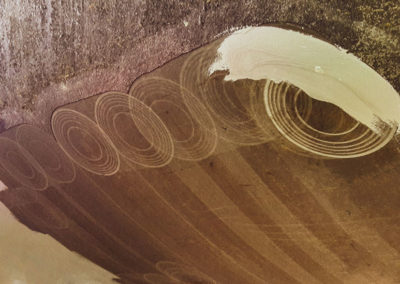

Penstock external surface.

Together with AMBPR and DONELLI companies, ACRI INGENIERIE has designed a ultra-high pressurewater jetting robot with full collection at source moving on the 2700 mm diameter outer surface.

Customer reference: DONELLI

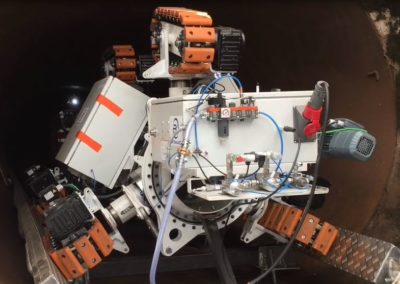

BONRIEU, project:

Penstock outer surface.

EDF has challenged us with the development of a robot able to circulate on the outer surface of a penstock. The robot has been successfully designed, manufactured and tested. water jetting stripping and painting has been made in the Alps, on the 700 mm diameter Bonrieu pipe.

Customer reference: ANTICORR

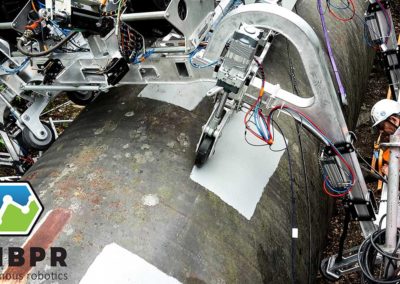

NAJAR, Project:

Penstock inner side.

Sand blasting and first layer painting robot used in the Najar (Pyrénées) penstock drain.

Inner penstock diameter 1800 mm.

Customer reference: Battakarst

Le Bens, Project:

Penstock inner side.

Sand blasting and first layer painting robot used in Le Bens (Alps) penstock.

Inner penstock diameter 900 mm. For this project we have designed a set of specific Motor driven reels for the robot’s cable including optical fiber, electrical supply, pickling pipe, sucking pipe and paint pipe.

Customer reference: Battakarst