Staff lift and platforms for civil engineering

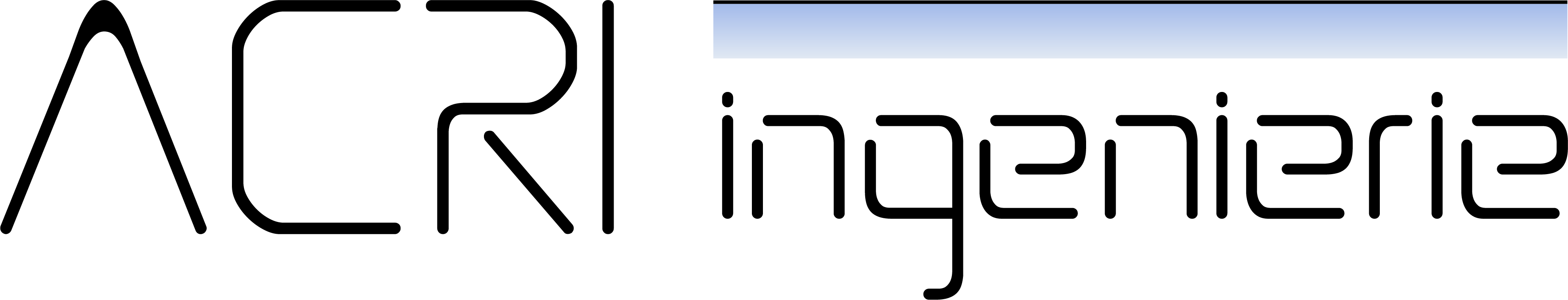

In 2013, ACRI INGENIERIE was selected for the PASSY (Alps) penstock replacement. The new penstock was to be placed in a 230 m mineshaft.

Thanks to our equipment, various operations have been successfully achieved: shotcreting, penstock installation, gap concreting and, finally, inner penstock stripping and painting.

This project was awarded as Regional Innovation Grand Prix from VINCI.

This first successful project has opened a way for several staff lifting equipment combined with material elevation.

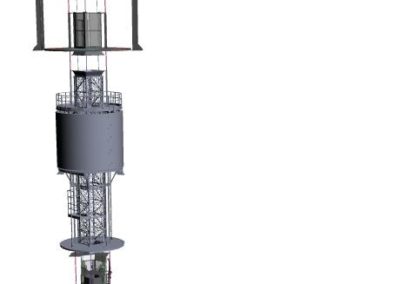

TELT Project:

Lyon-Turin European Tunnel

Thanks to our equipment, several operations are completed: shotcreting, welded mesh installation, rock drilling for steel bar anchoring. We have designed, produced, assembled and put in production two 120 T gantry, two 6 level platforms both linked to the surface with a lift and a freight elevator working independently. The lift has a 60 m/min speed and the freight elevator a 30 m/min one.

Those equipments, used 24/7 during 2 years will be replaced by a platform dedicated to the waterproofing and concrete formwork installation.

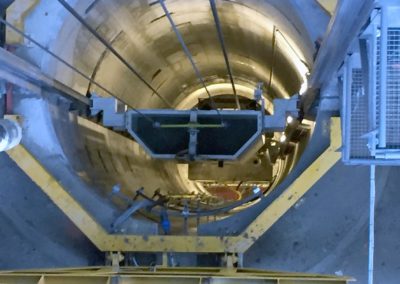

LIVET GAVET, Project:

We have supplied the full equipment required for the surge shaft concreting (180 m heigh, 5,5 m diameter): 20 T slipform on dual cables, transfer shuttle for people and concrete, outside cable-holding gantry.

Customer reference: CAMPENON BERNARD

PASSY (2), Project:

The PASSY penstock upper part, even if not replaced, has been pickled and paint.

ACRI INGENIERIE has created an inner rolling trolley transporting people on a 45° slope and allowing all required renovation operations inside the penstock.

Customer reference: PREZIOSO

Saint-Marin, Project:

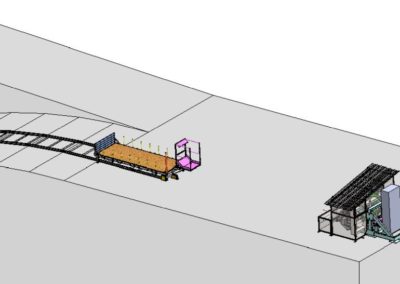

For a 90 m long, 54% slope gallery digging in “Saint-Martin sur la Chambre”, we have designed a rail guided transport platform with which all working material was carried up and down the gallery.

Customer reference: TP LYON

PASSY (1), Project:

innovative 3 in 1gantry:

• Holding working platform in a well,

• people transport,

• Modular platform for inner penstock painting activity.

Advantages:

Adaptable according the different phases and job configurations.

Flexible tool during all site steps with an adapted safety level for people and freight transport.

Platform design according the various well diameters.

Time saving and user friendly for operators, those machines allow an improved penstock mounting production rate and a shorter well securing.

Scope and functions:

Well wall securing with easy concrete spraying

Penstock pipes transport in the well

Concrete transport for gap filling

Customer reference CHANTIERS MODERNE